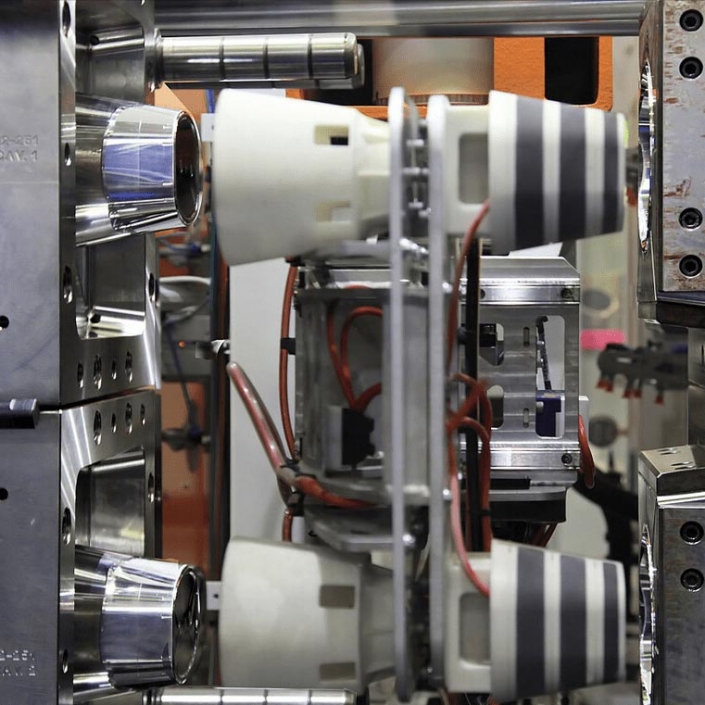

Tooling & Injection Molding

We make great tools for low-volume manufacturing,especially when quantity for hundreds and thousands of parts, we can use aluminum and Steel material to build the mold. To shorten lead-time and reduce cost, we share the mold base and different mold cavity. The material used will depend on the type of resin, characteristics of the parts and the number of parts you required.